QTY10-15 Block Making Line

clicks:2215|

Hollow Brick |

390*190*190 |

10pcs/mould |

|

Nozzle Brick |

240*115*90 |

28pcs/mould |

|

Solid Brick |

240*115*53 |

52pcs/mould |

|

Holland Brick |

200*100*60 |

36pcs/mould |

mould cycle

15-20s

mould area

1050×910mm

vibrating power

80KN

workshop area

500m2

total power

45.38kw

total weight

13.5T

install capacity

100KVA

over dimension

7380×2100×3090mm

pallet size

1100×950x25mm

Popular brick type

Brick size (mm)

Qty/mould

hollow brick

390×190×190

9

Nozzle brick

240×115×90

25

Solid brick

240×115×53

50

Holland brick

200×100×60

33

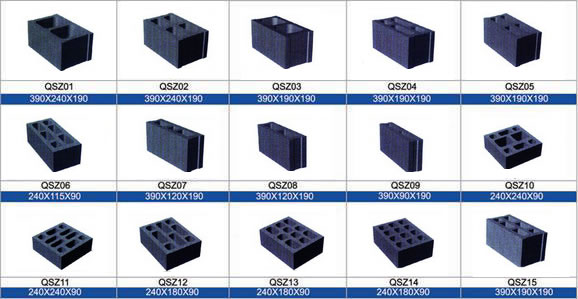

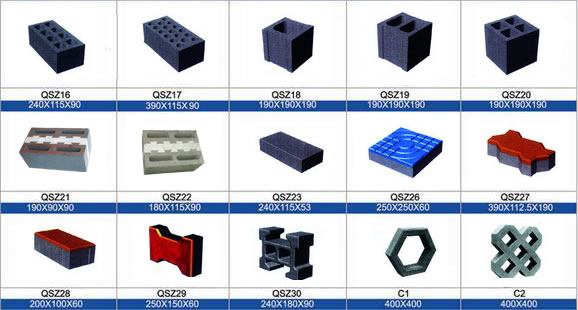

PRODUCT TYPE LIST

Search

NEWS

Online Service